Myceen's Insulation Materials in Visionary Timber Pavilion

Myceen x EKA PAKK Pavilion featured on Dezeen

Longer read here:

To date, the hygrothermal performance of mycelium-based composites has not been studied in comparison with conventional materials such as EPS or mineral wool. Myceen sees strong breakthrough potential in this field – the company’s bio-based composites offer a sustainable alternative to traditional materials while contributing to a healthier and more natural indoor environment. In November 2024, together with the Estonian Academy of Arts’ Timber Architecture Research Centre, Myceen opened the PAKK Pavilion in Tallinn, Estonia, to conduct a field test using mycocomposite insulation.

“Talking with architects, builders, and pre-fab house producers around Europe has given us confidence that the material is needed in the market,” explains Siim Karro, the CEO and Co-Founder of Myceen. “Our material is similar to wood fibre insulation that is already used, but its premium price tag is too often a turnoff. When we say that our material has a 4 times lower price, with even better properties, the next question is, where and when can we get it?” he adds.

First Successful Winter

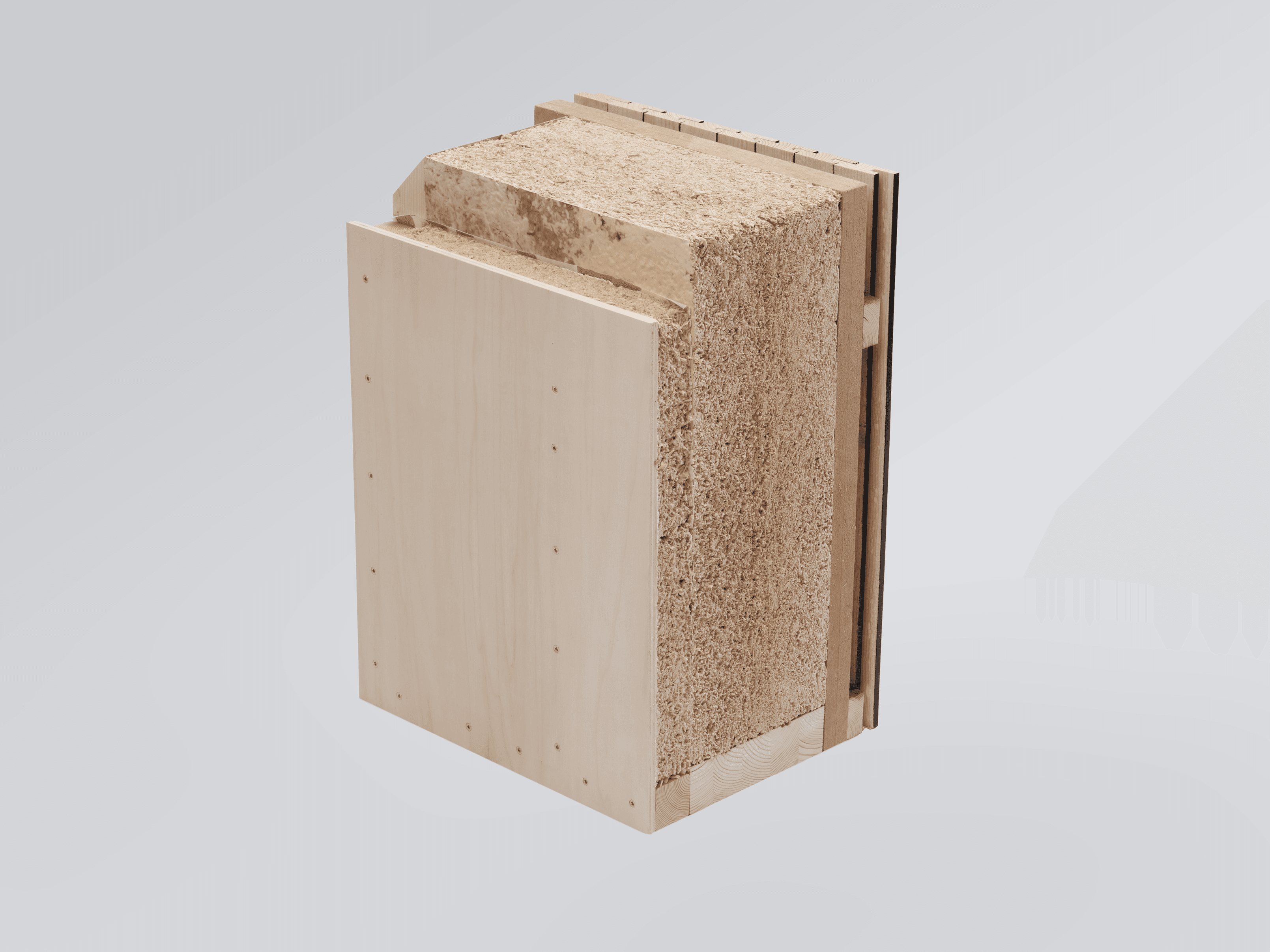

Since November 8, 2024, more than 80 sensors have been monitoring the hygrothermal performance of specially designed building envelope systems, using Myceen’s mycocomposites as the core insulation material. This evaluation, resulting in an MA thesis supported by Tallinn University of Technology, shows that mycelium-based insulation matches the thermal performance of mineral wool and wood fibre, while better regulating humidity and temperature.

“Preliminary results reveal no condensation or mould risks, demonstrating excellent moisture management for our biocomposites. Furthermore, measured U-values indicate superior thermal resistance compared to mineral wool under the same conditions,” notes Killu Leet, Myceen’s Head of Science.

The study will continue until the end of 2026 to confirm these promising findings, positioning Myceen’s bio-based insulation as a sustainable and highly effective alternative for modern construction.

Experimental Building Showcasing the Future of Timber Architecture

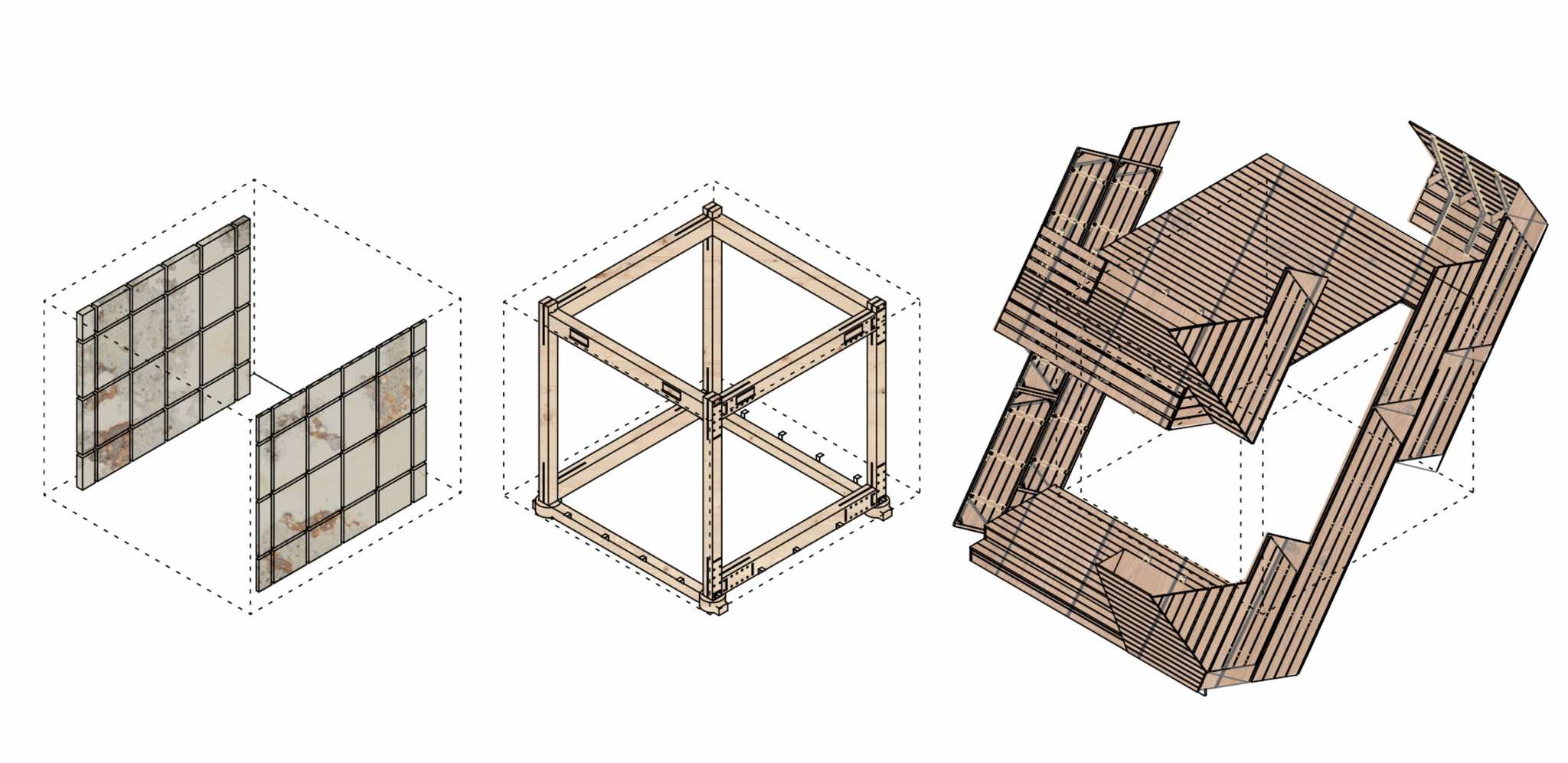

PAKK Pavilion is an experimental timber architecture research building in the centre of Tallinn. The pavilion combines work from three research groups’ ongoing projects:

- Myceen’s mycocomposite insulation materials;

- Pattern Building’s modular construction systems;

- sLender facade volumetric renovation system

Located between the medieval Old Town and the diverse Kalamaja subdistrict, the test house is situated in a public space to showcase research that is typically hidden in labs and academia.

Next Generation Building Materials are Healthy

The core of Myceen’s bio-based insulation consists of industrial residues such as sawdust. Mycelium, a natural biopolymer, acts as a natural glue that binds together wood particles into strong, high-performing building materials. The mycelium’s growth is fully halted with a specialised drying method. The resulting material is 100% toxin-free and safe, with the ability to improve indoor air quality.

Potential to make outdated fossil-based materials obsolete

Myceen’s insulation material properties outperform many conventional solutions:

- With a thermal conductivity of 0.037 W/mK, Myceen’s insulation boards offer solid thermal performance for energy-efficient construction;

- Fire class D in its natural state, without any additives, surpasses already conventional wood fibre insulation (class E).

- Similar to wood fibre insulation, mycelium composite regulates humidity by absorbing and releasing moisture without losing thermal performance. Its water vapour permeability helps prevent condensation, making it highly suitable for retrofit applications. This quality also improves indoor air quality.

- Made from upcycled by-products through an energy-efficient process. Verified by Life Cycle Assessment (LCA), the material has a footprint of –100 kg CO₂e/m³.

- The dense material stores heat efficiently, supporting stable indoor temperatures year-round. It’s designed to keep interiors cooler in summer and warmer in winter, making it well-suited for a wide range of climates.

Building material is first of all defined by its performance. The footprint and sustainability aspect have so far been a secondary or “good to have” feature. Although this is changing fast¹, giving a strong advantage to biofabricated materials like mycelium-based composites. Replacing traditional rock or glass wool insulation in an average timber-frame home with Myceen’s insulation can reduce the building’s carbon footprint by up to 20%.

“The New European Bauhaus initiative, launched by Ursula von der Leyen in 2020, called for new aesthetics in the built environment, thoughtfully combined with ethical construction. I believe Myceen insulation directly responds to this ethical dimension of materials, while also addressing the hidden layers within our walls. And what could be more future-oriented than a climate-adaptive building skin in times of uncertain environmental change?” Sille Pihlak, PhD, Dean of the Faculty of Architecture at Estonian Academy of Arts, Founder at PART Architecture

Market Waiting for Change

Europe has set strict targets to drastically lower emissions in every sector. The construction industry is one of the main contributors, with the existing building stock that needs to be renovated² to improve its energy efficiency. This sets the spotlight on new, low-footprint and ecological materials as we need to renovate 35 million buildings in 5 years³.

Although sustainability is often associated with expensive solutions that are out of reach for the masses, Myceen is addressing this directly. “New and sustainable solutions need to be affordable, otherwise they will be only available for niche markets and won’t create the necessary impact,” explains Myceen’s CEO, Siim Karro.

“Myceen’s building materials are highly anticipated in today’s market. An environmentally friendly insulation material with a competitive price point will certainly find application in both new constructions and renovation projects. In addition to providing excellent thermal performance, Myceen’s solution contributes to the well-being of building occupants in several ways – offering improved sound insulation, better protection against overheating and enhanced long-term durability.” Marek Mardisoo, MHM Product Manager at EstHus.

Investment Round, Scaleup and Pilot Projects

Currently, Myceen is raising their Seed round to scale up production and bring their insulation materials to the market. For pilot project inquiries, material samples or more information, contact Myceen directly at info@myceen.com.

PAKK Pavilion project partners:

Myceen’s novel mushroom mycelium-based wall insulation are monitored, and the performance is compared with conventional materials. The test house is one of the first buildings in the world to use mycelium-based insulation.

Pattern Building is an open-source industrial construction system developed at EKA PAKK based on modular and circular design. Researcher: Renee Puusepp

sLender facade is a study at EKA PAKK of the spatial possibilities of energy-efficient renovations. The project aims to improve daylighting, accessibility, and communal areas in standard apartment buildings that require renovation. Researchers: Sille Pihlak and Siim Tuksam

Architecture: Siim Tuksam, Sille Pihlak, Karl Erik Miller, Renee Puusepp Interior architecture: Siim Karro, Germo Ausin

The construction of the pavilion was supported by Kalvasta Timber, Viking Window, Thermory, RAITWOOD | Rait AS, Rothoblaas, Timberwise Oy, Silman.

Sources:

1 Denmark tightens the Limit CO2e Values for New Buildings

3 Renovation Wave sets a target to renovate 35M buildings by 2030